Ship inspections are crucial for the maritime industry to reduce accidents such as structural failures. A bowtie analysis can visualise omissions in inspection that lead to undesired events.

Structural failures account for 15% of inspection-related accidents in the maritime industry.

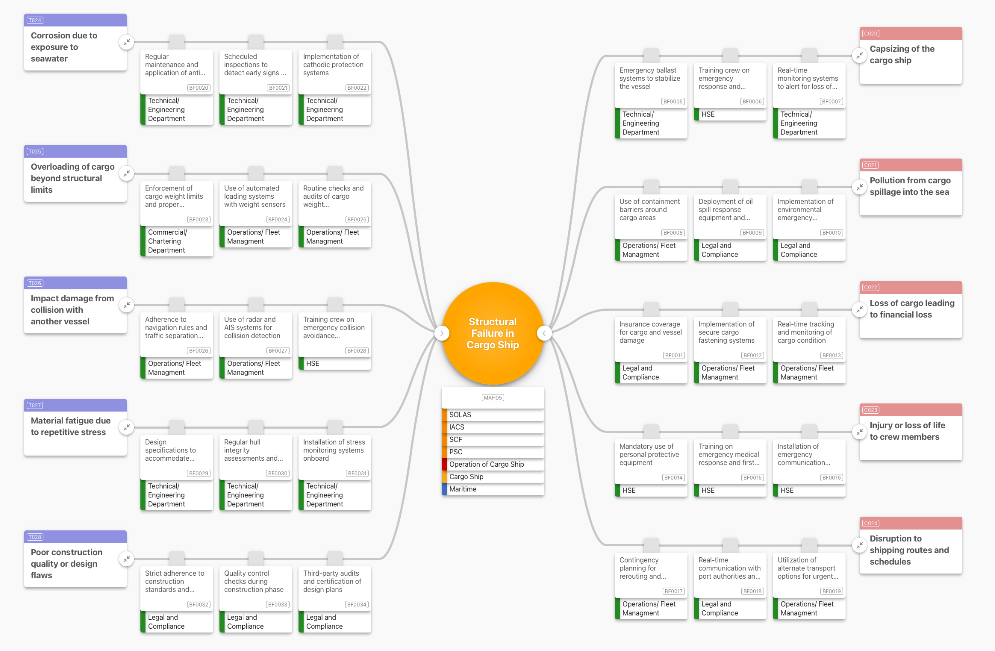

Here is a practical example of how bowtie analysis can help identify omissions in inspection and how they can escalate to major accidents such as a structural failure.

Click here to go to the bowtie in Presight OpenRisk: Structural Failure in Cargo Ship Bowtie – OpenRisk

Structural Failures

The bowtie diagram for structural failure accidents in cargo ships shows that poor maintenance and poor inspection are critical contributing factors. Intermediate causes like corrosion, cracking, and deformation, which might result from inadequate inspections, lead to structural failures. These diagrams help in identifying how omissions in inspection can escalate to major accidents.

An example highlighted in the analysis is the sinking of the general cargo ship ‘Swanland.’ Poor inspection and maintenance resulted in significant corrosion, which weakened the vessel’s structural integrity, leading to its eventual sinking. This case underscores the importance of regular, thorough inspections to prevent such structural failures and the catastrophic consequences that can follow. These ship inspections can become visible and be highlighted in a bowtie model. This is especially the case with the Presight Barrier Management system, where the status of ship inspections is shown in relation to a potential accident, such as a structural failure.

Using bowtie analysis software or comprehensive solution like Presight Barrier Management

Bowtie analysis, like OpenRisk, serves as a powerful tool in ship inspections within the maritime industry, offering a detailed and visual approach to understanding and managing risks. It enhances the ability to uncover potential hazards, evaluate inspection effectiveness, and ensure safer maritime operations. Examples like the Swanland sinking show how bowtie diagrams can highlight critical points where better inspections might have prevented the accident. This helps protect both crew and cargo.

A bowtie diagram showing “Structural Failure on Cargo Ship” as the top event. Click here to copy and edit the bowtie to make it your own: Structural Failure in Cargo Ship Bowtie – OpenRisk

For more control over your Barrier Management strategy, you can implement Presight Barrier Management allowing you to ensure compliance, and a proactive approach. With Presight Barrier Management, you can monitor the health of your barriers as part of your process safety strategy. This gives you a full overview of both human factors and technical elements. With Presight Barrier Management you can confidently demonstrate that your assets are safe and that you know it.