The 2010 Chilean Mining Accident

In 2010, 33 workers spent 69 days trapped inside the San Jose gold and copper mine after it collapsed on August 5th. The “Chilean mining accident” (2010 Copiapó mining accident) involved a rock fall that triggered a cave-in. Thanks to a long and intense rescue effort, all the miners survived making them the longest-known survivors of being trapped underground in recorded history.

Understanding Bowtie Analysis for Risk Management

Major accidents like these can be prevented, and risks can be better understood and mitigated using a bowtie analysis.

Click here to go to the bowtie on cave-ins in the mining industry in OpenRisk: Cave-ins and Rock Falls Bowtie – OpenRisk

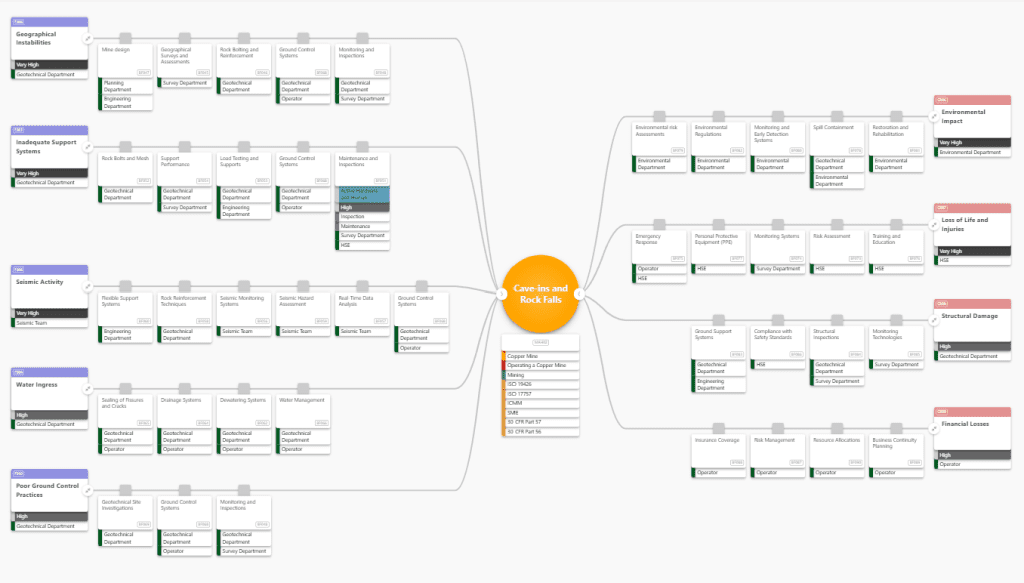

Bowtie analysis is a commonly used tool across the mining, energy, and oil and gas industries, among others. It’s a safety management method that simplifies complex risks by mapping them in easy-to-understand “bowtie diagrams.” While geographical instabilities can still occur, there are many modern techniques such as bracing ceilings and walls that help reduce the risk of cave-ins and rock falls.

Preventative Barriers: Stopping the Event Before It Happens

A bowtie analysis helps identify threats like geographical instability, poor ground control practices, and other contributing factors to cave-ins and rock falls. It also shows which measures called preventative barriers can be put in place to stop a major accident before it happens.

These preventative barriers might include solid mine design, effective ground control systems, and regular monitoring and inspections of cave conditions. They can also involve drainage systems and sealing of fissures and cracks.

Mitigating Barriers: Reducing the Impact When Things Go Wrong

Bowtie software tools, like OpenRisk, also visualises mitigating barriers measures that help reduce the impact if an unwanted event does occur. In the case of cave-ins and rock falls, these can include emergency response teams, training and education, a strong safety culture, and more.

The right-hand side of the bowtie diagram highlights the potential consequences of an incident, including injuries, fatalities, and financial loss.

Bowtie showing top event being Cave ins and Rock Falls. Click here to view the bowtie in Presight OpenRisk: Cave ins and Rock Falls

Making Mining safer

Accidents like the 2010 Chilean mine collapse serve as a powerful reminder of why proactive risk management matters. Bowtie analysis helps bring clarity, structure, and visibility to managing the risks involved in mining operations.

Want to learn more or explore tools that help improve safety and efficiency?

Visit OpenRisk to see how you can take the next step in preventing major accidents and enhancing operational resilience.

For more control over your Barrier Management strategy, you can implement Presight Barrier Management allowing you to ensure compliance, and a proactive approach. With Presight Barrier Management, you can monitor the health of your barriers, as part of your process safety management strategy to get a holistic overview of your human factors as well as your technical elements. With Presight Barrier Management you can confidently demonstrate that your assets are safe and that you know it.