Mining, while essential to the global economy, remains one of the most hazardous industries. Mechanical failures—along with factors like explosions and fires—are a leading cause of mining accidents. This highlights the need for strong safety measures and advanced technologies to reduce these risks.

According to a research study on mining accidents, the application of software or safety models is essential to minimise the number of mining accidents. Solutions like OpenRisk, a bowtie analysis software, can play a key role here by offering intuitive tools that help identify weak points before they escalate into incidents. Integrating such systems into everyday operations is a practical step toward smarter, more proactive risk management.

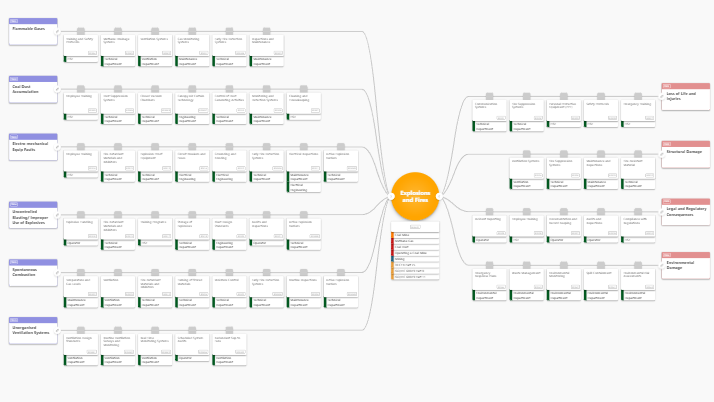

A bowtie showing top event for fire and explosion accident in the mining industry. Click here to copy and edit to make the bowtie your own: Explosions and Fires Bowtie – OpenRisk

Preventing Explosions: A Focus on Coal Mines

Coal mine explosions, particularly those caused by firedamp (methane gas) and coal dust, are among the deadliest hazards in the mining industry. An extensive investigation into gas explosions in Chinese coal mines from 1950 to 2015 highlighted several key causes, including:

- Unorganized Ventilation Systems: These can lead to the dangerous accumulation of firedamp, which is highly explosive.

- Illegal Blasting: Uncontrolled blasting can ignite gas or dust, leading to catastrophic explosions.

- Electromechanical Equipment Faults: Mechanical issues can spark fires or explosions, particularly in hazardous environments.

- Coal Dust Accumulation: This can lead to dust explosions if not properly managed.

These findings emphasise the need for stringent preventive measures to mitigate these risks.

Advanced Safety Measures

A variety of advanced safety measures have been developed to address these challenges, particularly in the context of coal mine explosions:

- Methane Credit Concept and Mine Classification: These involve categorizing mines based on their explosion risk and implementing appropriate safety measures tailored to each classification.

- Explosion-Prevention Technologies:

- Automatic Fire Warning Devices: Early detection systems that alert workers to potential fire hazards.

- Canopy Air Curtain Technology: This helps to minimise the spread of coal dust, reducing the risk of explosion.

- Fire-Retardant Materials and Inhibitors: Used to prevent the ignition and spread of fires.

- Active Explosion Barriers: These are designed to suppress explosions before they can cause widespread damage.

- Ventilation and Methane Drainage: Ensuring adequate ventilation and proper methane drainage is critical to preventing the accumulation of explosive gases.

- Coal Dust Management: Techniques such as water spray, scrubbers, and the canopy air curtain method help minimize coal dust generation. Additional measures include:

- Inertisation with Stone Dust: This prevents coal dust ignition.

- Use of Hygroscopic Salt: This reduces the risk of coal dust explosions.

- Closed Vacuum Chambers: These are employed for the suppression of coal dust generation.

The Role of Fuzzy Fault Tree Analysis (FFTA)

To further enhance safety, the Fuzzy Fault Tree Analysis (FFTA) method has been found effective in analysing coal mine explosion accidents. FFTA helps in identifying the root causes of accidents and provides insights into the most effective preventive measures.

The Fault tree analysis is the left side of the bowtie while the right-side of a bowtie is the Event tree Analysis (ETA). The bowtie used to visualise the pathways from potential causes of an event (hazards) to its consequences and to identify the barriers that can prevent or mitigate these outcomes.

Bowtie Analysis provides a comprehensive view of how risks can be managed by focusing on both preventing the occurrence of the hazard and mitigating its consequences. Using a bowtie software tool like OpenRisk allows mining teams to easily build, maintain, and share these analyses digitally – improving clarity, accountability and ongoing risk tracking across operations.

Here is an example of a bowtie in Presight OpenRisk: Explosions and Fires Bowtie – OpenRisk

The Ongoing Challenge

Despite significant technological advancements, coal mine explosions continue to occur worldwide, leading to both loss of life and economic setbacks. The persistence of these incidents over the last two decades highlights the need for ongoing improvement of safety practices and analysis through bowtie methodology.

Conclusion

The integration of advanced technologies and safety measures is essential to reducing the risk of accidents in the mining industry. While progress has been made, the continued occurrence of incidents underscores the importance of maintaining a proactive approach to safety. By embracing these innovations and preventive strategies, the mining industry can move closer to achieving a zero-accident future.

For more control over your Barrier Management strategy, you can implement Presight Barrier Management allowing you to ensure compliance, and a proactive approach. With Presight Barrier Management, you can monitor the health of your barriers, as part of your process safety management strategy to get a holistic overview of your human factors as well as your technical elements. With Presight Barrier Management you can confidently demonstrate that your assets are safe and that you know it.