Forklift incidents are becoming increasingly common and costly on construction sites. In 2023, forklifts were responsible for 67 work-related deaths. From 2021 to 2022 there were 24,960 cases involving days away from work, job restrictions, or transfers (DART cases) . Since 2013 the number of forklift related injuries involving days from work have increased from 6 820 to 7 740 cases the National Safety Council has reported . Many of these are from transportation and warehousing, goods and service providing industries followed by manufacturing industry, and then by the construction industry . It is evident from these numbers that forklift related incidents have increased in the recent years.

Why forklift incidents are increasing

This increase can be linked to several factors. One is the introduction of new equipment without sufficient training for operators. Mechanical issues, outdated machinery, and poor maintenance routines also play a significant role. In addition, as the forklift market continues to grow, more trucks are being used, resulting in greater exposure to risk .

Many of workplace injuries could be avoided through better planning, training and safety measures.

How bowties help prevent accidents

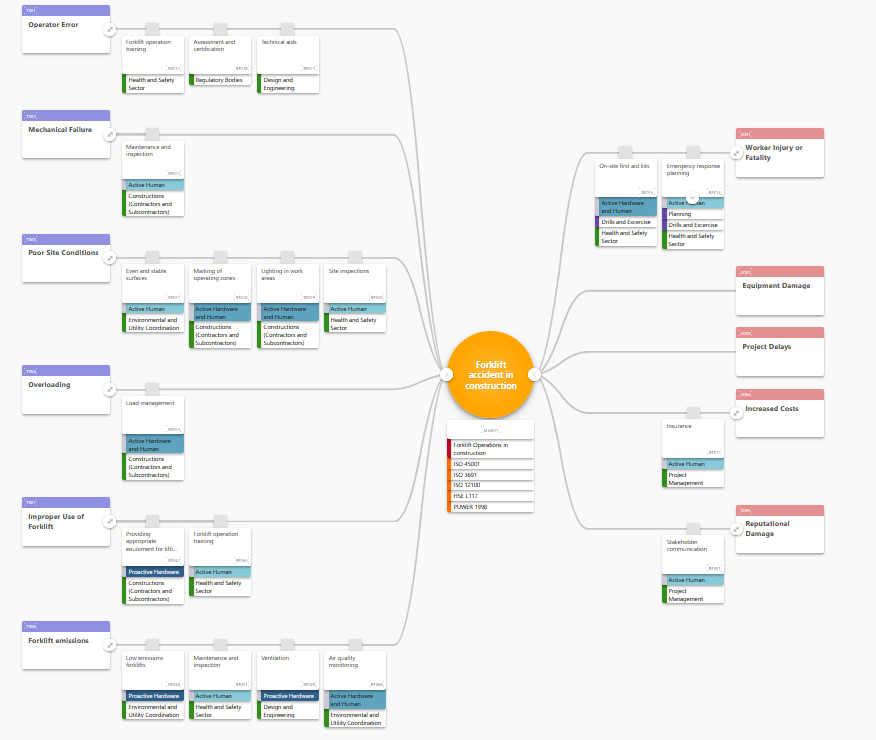

With the bowtie methodology, it is easy to map out potential threats to a forklift accident happening such as mechanical failure, overloading, improper handling and use of a forklift and more.

To see the bowtie in Presight OpenRisk click here: Forklift accident in construction 0.2 Bowtie – OpenRisk

Preventing forklift incidents before they happen

A bowtie diagram is a powerful visual tool that helps construction and site safety professionals identify and manage the risks associated with forklifts. On the left side of the bowtie, there are outlined preventive barriers such as:

- Operator and construction safety training and certification

Ensures that drivers have the necessary knowledge and skills to operate forklifts safely thus reducing the risk of human error.

- Marking of operating zones such as clearly marked pedestrian and vehicle zones

Helps prevent collisions by physically separating people from moving equipment in busy areas.

- Load management of weight and balance checks

Prevents tipping or load drops which are common causes of serious forklift incident including fatalities

- Regular equipment maintenance

Detects and addresses mechanical issues before they lead to dangerous situations.

On the right, mitigating measures such as emergency response planning and stop procedures, and first air kits on the construction site which will help reduce the potential consequences of forklift related accidents.

Bowties help make risk scenarios more understandable and actionable to map out how incidents unfold and more importantly, how to stop them from happening in the first place.

Read more on how to use bowties in unwanted events on construction site here: How to use the bowtie methodology in construction

By visualising scenarios in a bowtie format, it becomes much easier to communicate risks across teams and ensure everyone on site understands their role in preventing incidents.

A proactive approach to forklift safety

The example bowtie below demonstrates how elements like valid training certificates, regular maintenance logs, and physical barriers work together to create a safer site. Each barrier element and barrier function reduce the chance that a single failure will lead to an accident.

By implementing a bowtie methodology, construction companies can improve compliance with construction safety regulations, raise awareness of construction risks, and cultivate a proactive safety culture.

Click here to see the bowtie in Presight OpenRisk: Forklift accident in construction 0.2 Bowtie – OpenRisk

Take action with OpenRisk

Ready to strengthen your site’s forklift safety?

Start using OpenRisk to create and manage digital bowties that make risk clear and actionable. Take the first step toward safer forklift operations with OpenRisk and start mapping your risks today: openrisk.presight.com