How to prevent Slip and Trip accidents with Bowtie Analysis

Slip and trip accidents remain one of the most common causes of injuries in the construction industry. Despite their seemingly low severity compared to falls from height or equipment-related incidents, slips and trips lead to thousands of lost working days, serious injuries, and even fatalities each year. In fact, according to global data, they account for over 30% of non-fatal workplace accidents. The reality? These incidents are almost always preventable, but only if we stop, assess, and act before someone gets hurt.

That’s exactly where the STOP routine comes in.

STOP stands for:

- Stop

- Think

- Observe

- Proceed

Rather than walking blindly into a task, STOP encourages workers to pause and actively assess the environment around them. Is the floor uneven? Are there cables lying around? Is it slippery? STOP turns passive observation into active risk assessment, embedding situational awareness into every movement on site.

Creating this kind of awareness on an individual level is only part of the solution. To ensure such routines are consistently applied and understood across teams, some organisations use structured tools like OpenRisk to document and communicate safety practices more effectively.

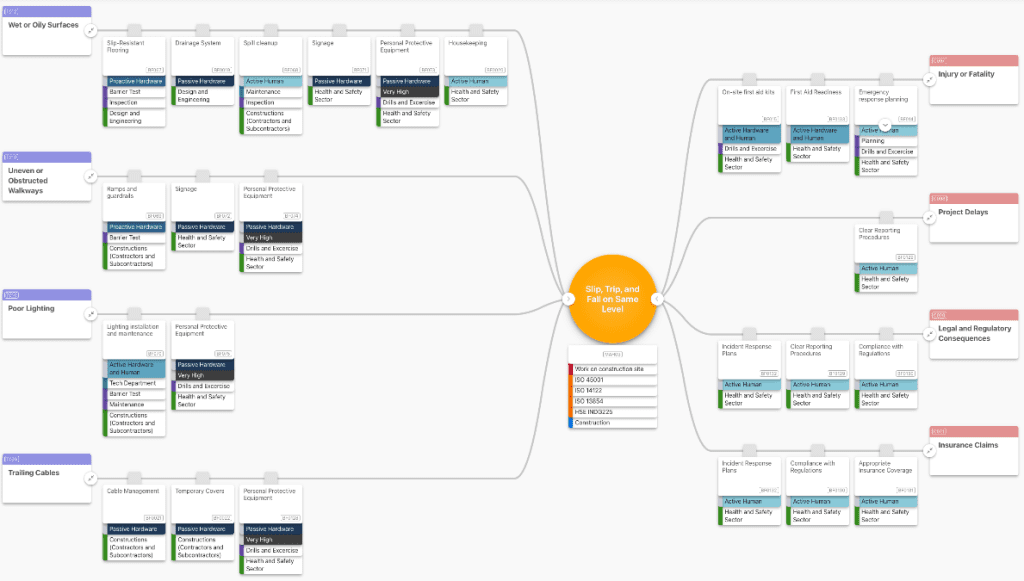

A bowtie diagram showing a slip, trip and fall accident as a top event. Click here to copy and edit the bowtie to make it your own.

This routine is not just about behavior, it’s about creating a culture of responsibility and about safety culture. The STOP routine reinforces the idea that safety is everyone’s job, every moment of the day.

Why Slips and Trips Deserve More Attention on Site

In construction, the environment is constantly changing. Materials get delivered, tools are moved, weather changes surfaces. A dry scaffold walkway in the morning might become dangerously slick by midday due to rain or spilled fluids. Add uneven surfaces, poor lighting, or time pressure and the risk increases.

While a slip might seem minor, it can lead to broken bones, head injuries, or long-term musculoskeletal problems. For HSE leaders, the cost isn’t just physical, it’s financial, operational, and reputational.

Using Bowtie Analysis to Prevent Slip and Trip Accidents

One of the most effective tools for systematic prevention is the Bowtie method. Instead of simply reacting to incidents, Bowtie Analysis, like OpenRisk, helps you visualise the risk landscape around a specific hazard, like slippery surfaces or trip hazards. In addition a bowtie analysis method, not only considers technical elements such as safety critical equipment, but also human factors such as Safety Culture Training.

For a slip and trip hazard, the bowtie could have the following barrier elements:

- Threats: Wet surface, cluttered path, poor lighting, trailing cables

- Preventive Barriers: Drainage systems, proper housekeeping, temporary covers, good safety culture training, lighting checks, cable management

- Consequences: Worker injury, lost work time, insurance claim, legal investigation

- Mitigating Barriers: First aid readiness, clear reporting procedures, rapid clean-up response

Click here to go to bowtie in Presight OpenRisk: Slip, Trip, and Fall on Same Level Bowtie – OpenRisk

By mapping these elements in a Bowtie diagram, people can clearly see where controls exist, where they are weak, and where new barriers need to be introduced. It also supports toolbox talks, audits, and safety campaigns with visual clarity and structure.

What Can HSE Professionals Do Today?

- Implement and promote the STOP routine across all teams, make it part of daily briefings and permit-to-work processes.

- Use Bowtie Analysis for common but underestimated hazards like slips and trips. Don’t wait for a major accident to take them seriously.

- Engage frontline workers in identifying threats and suggesting barriers. Those closest to the hazard often see what management misses.

- Track and audit barriers regularly. It is not enough to have signage or non-slip mats, they need to be maintained, inspected, and respected.

- Document incidents and near misses. Use them to update Bowtie diagrams and improve response systems.

Final Thought

Slips and trips are not just “clumsy moments”, they are serious safety failures. But with the STOP routine as a daily habit and Bowtie Analysis as a structured planning tool, construction sites can become significantly safer. This will create an environment where awareness and responsibility are the norm, not the exception. Digital tools like OpenRisk, allow you to easily apply Bowtie method thinking in practice, helping teams visualise threats, barriers, and responsibilities more clearly, and keeping safety front of mind.