In the energy sector, the presence of hazardous substances such as toxic gas releases is a reality. Among these, toxic gases such as hydrogen sulfide (H₂S), ammonia (NH₃), or chlorine (Cl₂) pose invisible yet deadly risks to workers, the environment, and surrounding communities. Despite rigorous safety systems, incidents involving toxic gas releases still occur, often with severe consequences. Software tools such as Presight OpenRisk can help structure and visualise risk scenarios, making it easier to identify weak points and manage barriers effectively.

The Nature of the Hazard

Toxic gas releases are often colourless, odourless, and can be lethal in low concentrations. Because of these invisible qualities, it can be difficult to perceive the hazards associated with working with these gases. Workers may unknowingly enter contaminated areas or continue operations while being exposed to dangerous levels. Similarly, system failures that lead to gas releases can be hard to spot until concentrations reach critical levels, as there are often no immediate visual or sensory warning signs. This makes the storage, transport, and use of these gases particularly challenging.

Why Toxic Gas Releases Still Happen

While modern oil and gas facilities, chemical plants, and power generation sites invest heavily in preventive measures, such as corrosion monitoring, automated gas detection, regular maintenance protocols, and staff training, gas releases still occur due to the complex interplay of system conditions, organisational factors, and environmental pressures. Rather than simple human error, incidents often result from gaps in system design, inadequate procedures, conflicting operational demands, or situations where workers must adapt to unexpected conditions with insufficient support or information. The complexity and interdependence of industrial systems mean that even minor deviations can escalate rapidly if the underlying system conditions don’t adequately support safe performance under varying circumstances.

Incidents like the Bhopal disaster, in 1984, remind us of how quickly things can go wrong when organisations lack sufficient or coordinated risk management. A gas leak at a pesticide plant in Bhopal, India, released methyl isocyanate into the air, killing thousands and injuring hundreds of thousands. Largely due to failed safety systems, poor maintenance, and lack of emergency preparedness.

Barrier-Based Thinking: A Better Way to See Risk

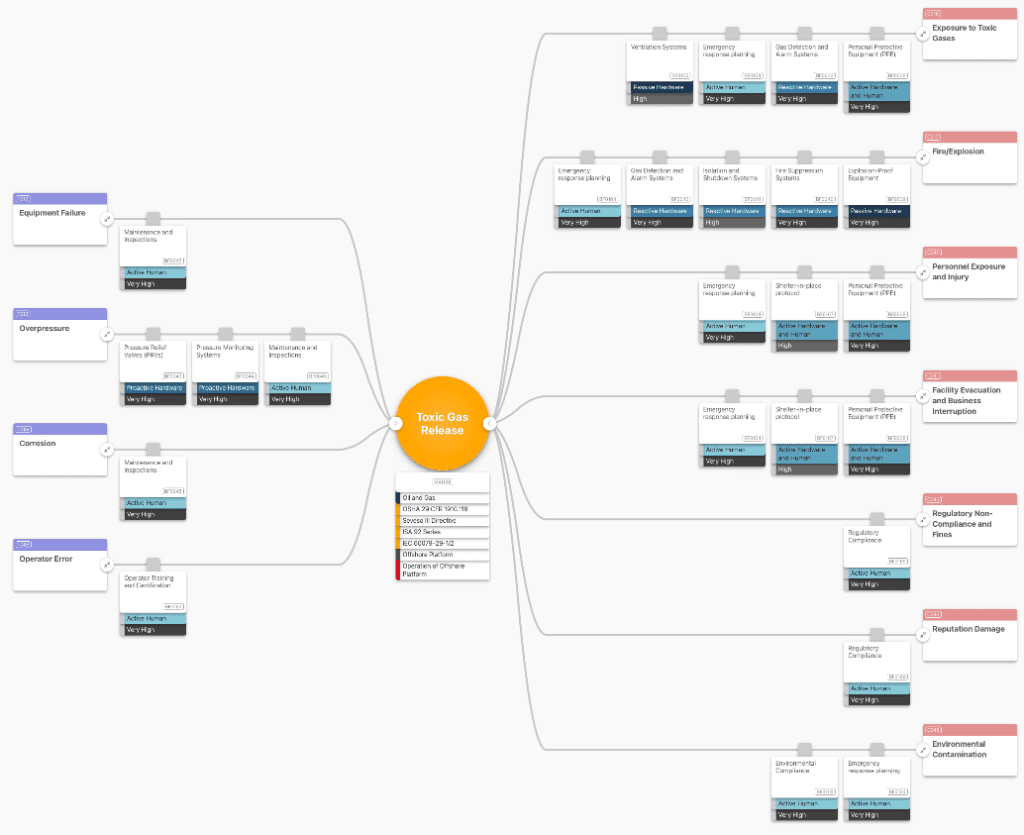

Barrier-based risk management methods, such as bowtie analysis, provide a comprehensive yet easy to use approach to understanding risk scenarios. The bowtie method helps visualise the complete picture of a hazardous event, from the threats that could cause it, through the preventive and mitigating barriers in place, to the consequences if those barriers fail. This holistic view enables teams to identify how different safety measures work together, differentiate between various types of barriers and their effectiveness, and prioritise improvements based on the overall strength of their barrier systems.

Explore Toxic gas release bowtie in Presight OpenRisk here: Toxic Gas Release Bowtie – OpenRisk

By mapping out these relationships, companies can identify weak spots in their defenses and improve not just compliance, but real-world safety outcomes.

From Analysis to Action: Using Tools Like OpenRisk

While understanding the nature of industrial hazards is essential, turning that knowledge into effective action requires the right digital tools.

Platforms like OpenRisk make it easier for teams to build and visualise your full risk picture. While Presight Barrier Management platform can help you maintain bowtie models, track and monitor barrier health, and integrate data from operations and audits.

With Presight Barrier Management you can confidently demonstrate that your assets are safe and that you know it.

A Shared Responsibility

Toxic gas releases are not just technical problems, they are human, environmental, and organisational challenges. Effective management requires awareness at every level, from frontline operators to top leadership. Barrier thinking, supported by the right tools, can help shift organisations away from a reactive stance and toward proactive prevention.

As the energy sector moves toward cleaner, safer, and more transparent operations, open approaches to risk communication and analysis will play a critical role. Because when it comes to toxic gases, what you don’t see can hurt you, but what you understand can save lives.