How the bowtie methodology be used in an accident investigation?

The bowtie methodology is a risk management tool that provides a holistic visual representation of the risk picture, making it invaluable for accident investigation. It visualises the threats, consequences, preventive and mitigating measures of a risk event in one picture.

This structured layout enables investigators to analyse the incident, identify root causes, and understand how a range of factors interact and lead to the top event.

The bowtie methodology

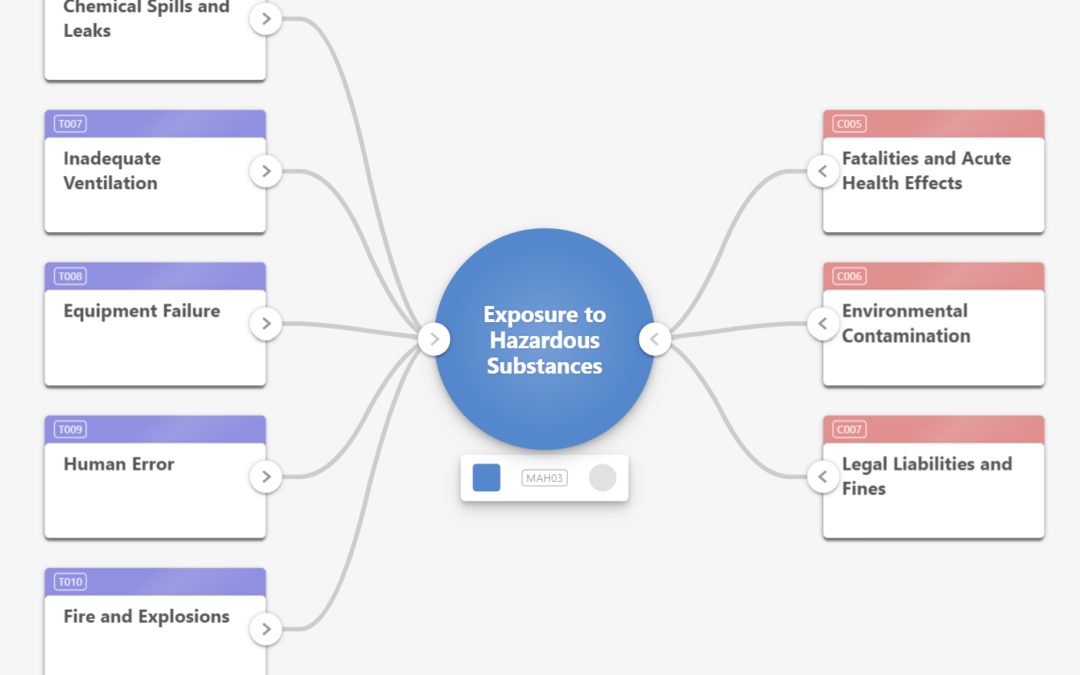

A bowtie diagram is a risk management tool that visualises risks in a clear and understandable way. Shaped like a “bowtie,” this diagram displays preventive measures on the left, recovery measures on the right, and the top (or main) event in the centre. This layout provides a comprehensive overview of the risk landscape in a single picture.

1. Top event (main event)

The central event where control over a hazard is lost. For instance, in the context of a subsea blowout, the main event could be the uncontrolled release of crude oil or natural gas due to pressure control systems failure.

2. Identify Hazards

Determine the hazard that led to the top event. Hazards are potential sources of harm that could lead to an accident.

3. Threats (Causes)

Located on the left side of the bowtie diagram, causes are factors that can lead to the top event. These can include weather conditions, equipment failure, or human error. For example, in a subsea blowout, causes might be blowout preventer failure, well leakage, or improper handling of the blowout preventer (BOP).

4. Consequences

Shown on the right side of the diagram, consequences are the specific outcomes of the top event. For a subsea blowout, consequences might include personnel injury, ignited blowout at sea, or environmental discharge.

5. Preventative Barriers

These barriers are designed to prevent the top event from occurring. They are placed on the left side of the bowtie diagram and include measures such as equipment maintenance and proper training protocols.

6. Mitigative or Recovery Barriers

Positioned on the right side, recovery barriers aim to minimize the impact of the top event if it occurs. Examples include emergency response plans and containment measures.

Manufacturing and control room

What is a bowtie model and why use it for risk managementSelecting an Accident Analysis Methodology

Understanding the causes of accidents leads to the development of better strategies to prevent accidents and mitigate negative consequences.

The main part of an accident investigation is the accident analysis, which involves systematically connecting the causes of the accident (Ahmadi, O., Mortazavi, S. B., Khavanin, A., & Mokarami, H. 2019).

There are different methods for conducting an accident analysis, and the ‘right’ methodology depends on the context of the accident.

When choosing an accident analysis methodology, it is crucial to consider the following aspects:

1. Ease of understanding, validity, and reliability.

2. The methodology should be straightforward and not too complex to ensure that different stakeholders with varying levels of expertise can understand it.

3. It should provide insights that align with the aims of the investigation, helping to answer the questions posed at the start.

4. Additionally, a reliable methodology will yield consistent results if the investigation is repeated.

The bowtie methodology excels in meeting these criteria, making it an excellent choice for accident investigation.

Its visual nature makes complex risk scenarios accessible and comprehensible to all stakeholders, regardless of their technical expertise. By mapping out the causes, the main event, and the consequences, the bowtie diagram helps investigators understand how different elements interacted to cause the accident. Furthermore, the systematic approach of the bowtie methodology ensures that repeated investigations will produce consistent results, enhancing the reliability of the findings.

Conducting a bowtie incident analysis for accident investigation

Presight OpenRisk is a free software tool for creating a bowtie incident analysis. Conducting a bowtie incident analysis for accident investigation involves a systematic approach to uncovering the root causes, understanding the sequence of events, and evaluating the effectiveness of safety barriers.

Here are the steps to conduct a bowtie incident investigation analysis:

- Gather Information: Collect all relevant data about the incident. This includes eyewitness accounts, equipment logs, maintenance records, procedural documents, and any other pertinent information. The goal is to have a comprehensive understanding of the circumstances surrounding the incident.

2. Identify the Top Event: Define the central event where control was lost, leading to the accident. This is known as the top event and is positioned at the centre of the bowtie diagram. For example, in the context of a subsea blowout, the main event could be the uncontrolled release of crude oil or natural gas due to pressure control systems failure.

3. Determine Threats (Causes): Identify the factors that contributed to the top event. These threats are displayed on the left side of the bowtie diagram. Examples of threats include equipment failure, human error, adverse weather conditions, or inadequate safety procedures.

4. Assess Consequences: Identify the outcomes that resulted from the top event. These consequences are shown on the right side of the diagram. Consequences might include injuries, environmental damage, project delays, or financial losses.

5. Identify Preventive Barriers: Document the measures that were supposed to prevent the top event from occurring. These preventive barriers are placed on the left side of the diagram, adjacent to the threats. Examples include regular equipment maintenance, safety training, and adherence to operational procedures

6. Identify Recovery Barriers: Document the measures that were in place to mitigate the impact of the top event once it occurred. These recovery barriers are positioned on the right side of the diagram, next to the consequences. Examples include emergency response plans, medical aid availability, and containment procedures.

7. Analyse Barrier Effectiveness: Evaluate the effectiveness of the preventive and recovery barriers. Determine whether they functioned as intended and identify any failures or weaknesses. This step involves scrutinizing the barriers to understand why they failed and how they could be improved.

8. Create the Bowtie Diagram: Using the information gathered, construct the bowtie diagram. Place the top event in the centre, threats on the left, and consequences on the right. Insert the preventive and recovery barriers accordingly. This visual representation helps clarify the sequence of events and the interaction between different elements.

9. Review with Stakeholders: Present the bowtie diagram to relevant stakeholders, including management, safety officers, and employees involved in the incident. Gather their input and perspectives to ensure that all aspects of the incident are understood and that the analysis is comprehensive.

10. Identify Root Causes: Delve deeper into the threats to identify the root causes of the incident. Understanding the underlying issues that led to the threats can provide valuable insights for preventing future occurrences. For instance, by using the ‘five times why’ methodology.

11. Implement Corrective Actions: Based on the findings, develop, and implement corrective actions to address the root causes and improve the effectiveness of safety barriers. This might include revising procedures, enhancing training programs, or upgrading equipment.

12. Document and Report: Compile a detailed report of the incident investigation, including the bowtie diagram, analysis, findings, and recommended corrective actions. Ensure that the report is accessible to all relevant stakeholders and is used to inform ongoing safety improvements.

13. Monitor and Follow-Up: Continuously monitor the implementation of corrective actions and the effectiveness of the revised barriers. Regular follow-up ensures the improvements are sustained and the risk management and barrier management process remains robust.

Conclusion

The bowtie methodology provides a structured, clear, and reliable approach to accident investigation. By visually representing the entire risk picture, from causes to consequences, it enables a thorough understanding of how accidents occur and how they can be prevented in the future.

The bowtie methodology helps in systematically dissecting an accident to understand its root causes and the effectiveness of existing controls, ultimately leading to improved safety and prevention strategies.

Presight OpenRisk can help with this retrospective investigation process. Click here to get started today with a free tier: OpenRisk

References:

This article was made with the help of AI