Presight PipeSpec

Standardises and tailors valve and pipe specifications to ensure compliance, enhance operational reliability, and improve efficiency, meeting the unique needs of each plant and process

Standardise your technical requirements for pipe and valve specifications with the latest datasheets revisions.

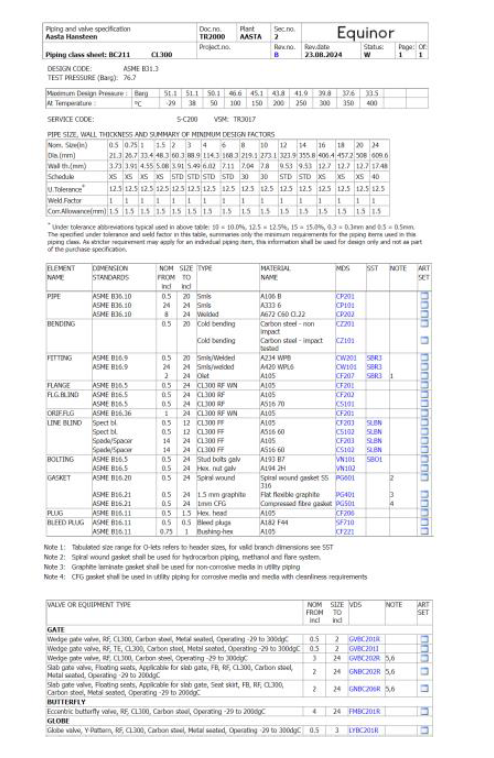

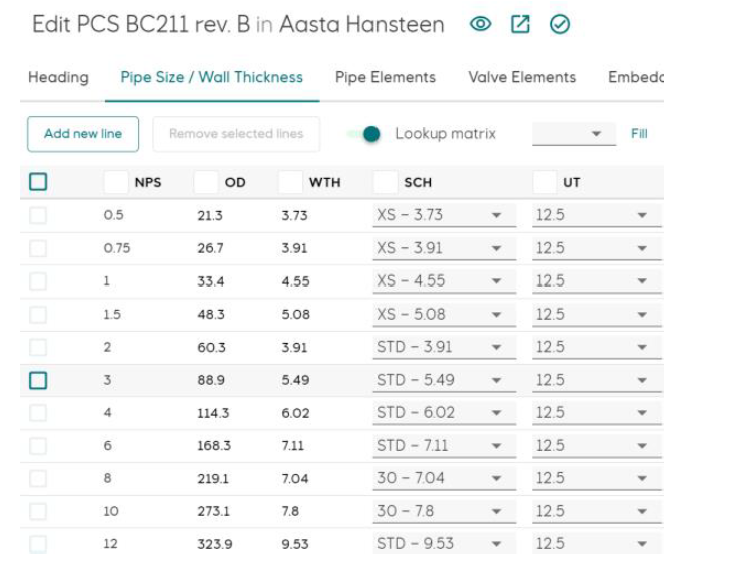

Presight® PipeSpec is a Piping and Valve Specification System, developed by Presight Solutions together with Equinor. The basic principles of the system is to standardise requirements to components and to tailor the menu of Piping Class Sheets (PCS) to each plant´s need such as the process requirements.

For each plant, all relevant datasheets are collected in an Issue. The Issue contains a set of plant specific PCS´s, with specific revisions of all referenced datasheets such as MDS, VDS and much more. To avoid frequent changes of a plant specific Issue, an Issue is not always updated to include the latest revision of datasheets referenced from PCS.

:

Why choose Presight PipeSpec:

Consistency

Collecting all relevant data sheets and revisions in a singular system improves oversight and control. It allows for quicker access to the necessary specifications, making it easier for teams to follow updates and maintain accuracy in their operations. You can define all your specifications in one place, ensuring consistency by choosing components from a predefined list.

Transparency and Availability

This makes information easily accessible to everyone involved in operations, creating transparency across the organisation.

Quality Assurance and Compliance:

Standardisation inherently boosts compliance with both internal policies and external regulations. Quality control is simplified as each component selected from the system adheres to predefined criteria, ensuring a high standard of safety and performance. The content of the texts are then validated to assure quality. This is achieved through the use of “signals” that indicate whether it is compliant or not. If a signal is red, it needs to be reviewed.

Historical Data

All data revisions are stored, making it easy to follow the history and view previous revisions of a particular datasheet.

Standardisation

By standardising the requirements for components and tailoring them to specific process needs, you create a safer and more efficient process. You can assure to meet industry standards and process requirements. This eliminates the guesswork and inconsistency in selecting parts, leading to more efficient design processes and procurement cycles.

Adaptability to Project Specifics

While the system provides a standardised approach, its flexible nature allows for adjustments based on the unique requirements of each project or plant, ensuring that the specific needs of every operation are met efficiently.

PipeSpec features

Cloud based SaaS solution

Fully web based with responsive design

Structured information together with embedded html editor that can include images and matrixes

Includes the following datasheets: PCS, VDS, MDS, VSK and EDS

Status and revision functionality with optional naming and revision numbering

Cascade updates and automatic change log

Information on revision changes

Role-based access control with read only access to your partners, contractors and vendors

Reports and search functionalities